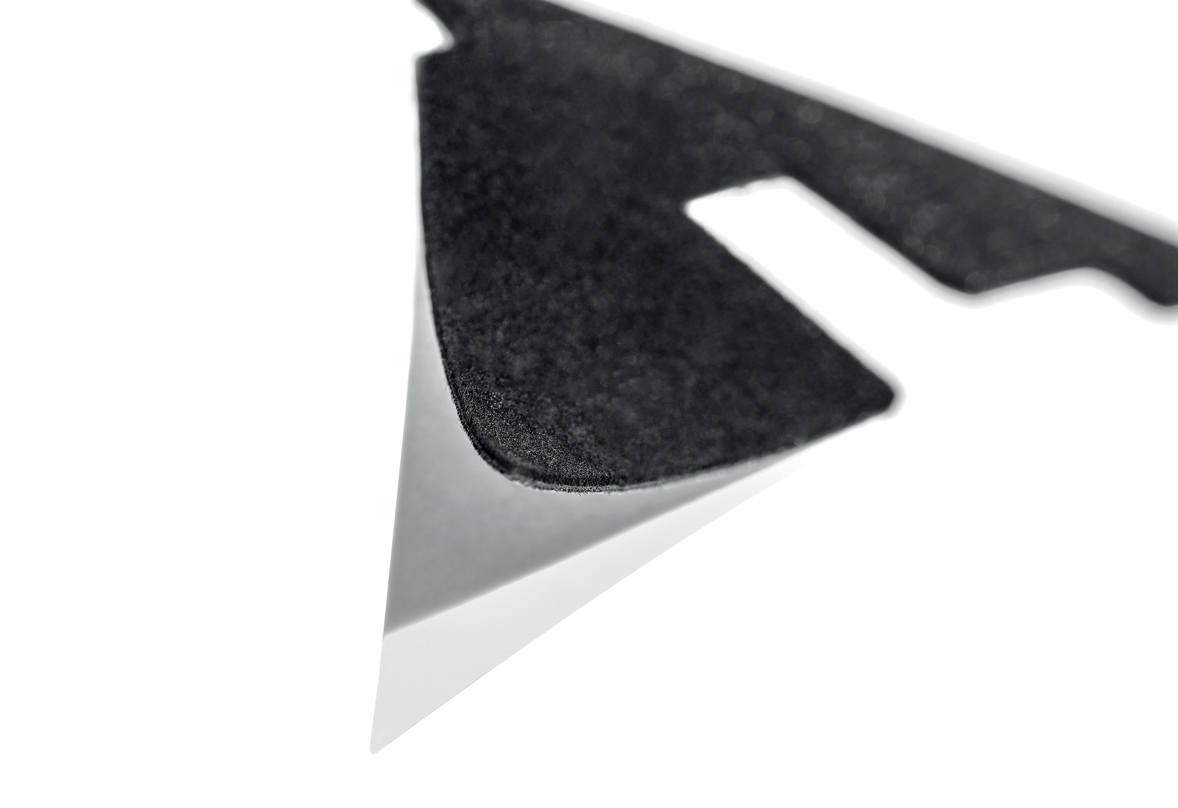

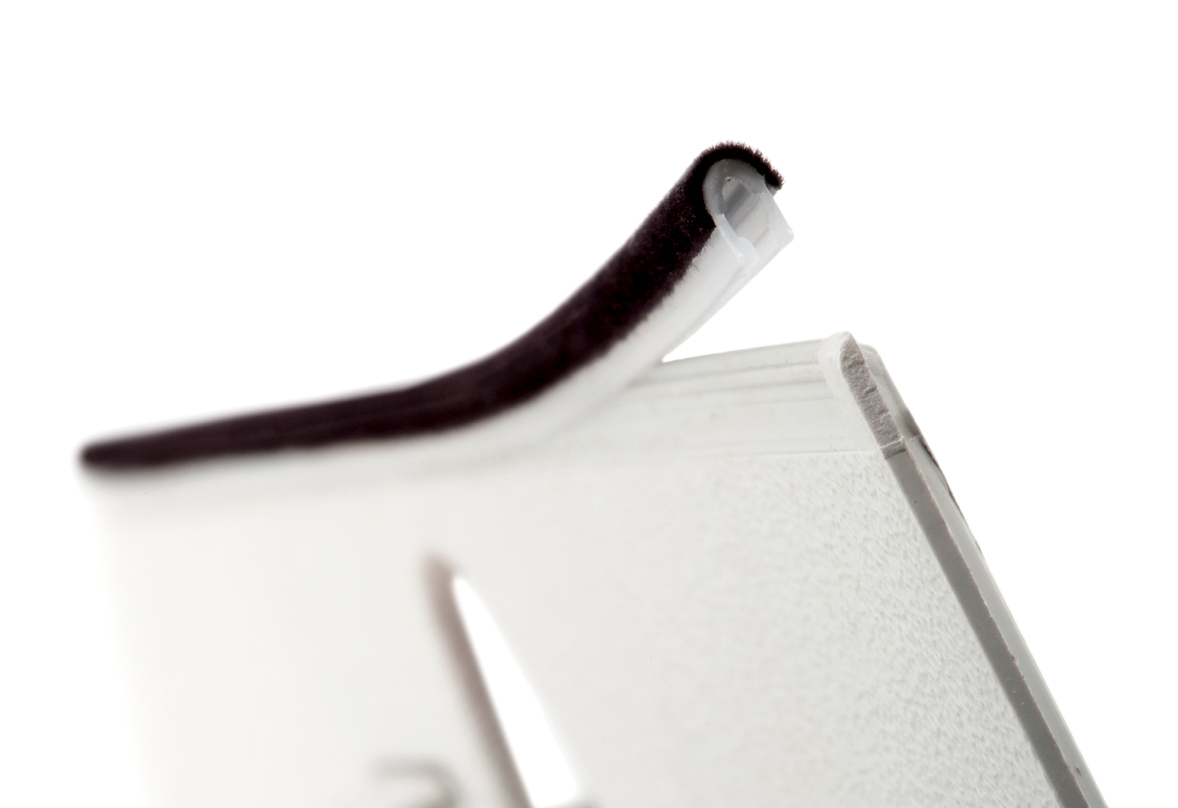

Taplasticker®

The best solution to reduce flocking complexity in processes where applying the flocked solution during injection is not feasible.

MATERIALS

Technical Information

Self-adhesive, die-cut flocked part, custom-designed for applications where a flocked solution is needed but direct chemical bonding is not possible. A flexible and reliable alternative, tailored to customer needs in shape, material and adhesive performance.

Flock FIbers

PES / PA

1,7 / 3,3 Dtex

0,4 - 0,8 mm

Adhesive

Over 30 years of experience in water-based adhesives

Support

Available with a self-adhesive textile or plastic base and compatible with different materials to suit your needs.

Other product options

Coated and Color

Coated

Flocking solutions with various coating options applied to the flocked surface to mitigate the risk of freezing or enhance advanced soundproofing. Thanks to our application technology, a homogeneous and uniform coating application is guaranteed, achieving high performance compared to other methods which directly result in savings for our customers.

Color

Self-adhesive flock solutions customized according to customer color requirements, designed to achieve an aesthetic finish that meets the highest quality standards. They are especially suitable for visible areas that require specific development, capable of meeting both functional and visual differentiation expectations.

APPLICATION AND CONSIDERATIONS

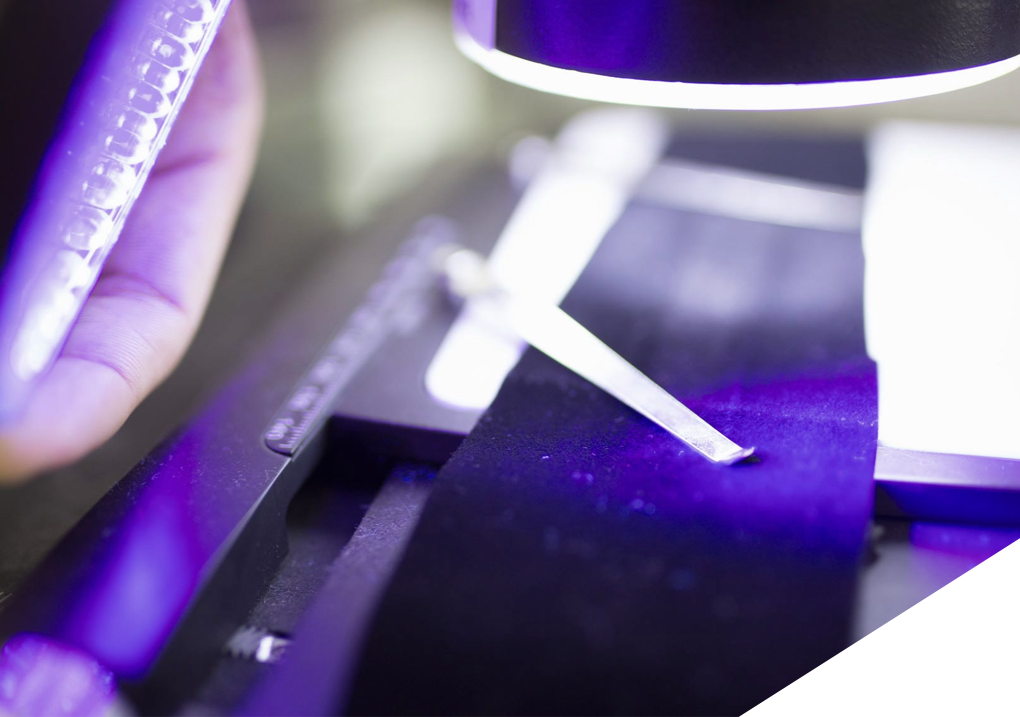

Taplasticker® Application

How is it applied?

Taplasticker® is attached to the part manually or through an automated process using pressure and proper positioning during the manufacturing process.

It provides greater flexibility for application and adaptation to change. It can be applied to different materials, meeting the highest requirements in the industry.

Considerations for the application of Taplasticker®:

- Preparation requirements for the surface where the Taplasticker® will be applied.

BENEFITS

Unique advantages of using Taplasticker®

Risks reduction in the flocking process

Flocking space reduction

Manteniance costs reduction

Cleaning costs reduction

High adaptability to changes in specifications and requirements

Waste reduction caused by flocking process

Higher fiber density and greater abrasion resistance

Possibility of incorporating coated flocking without additional steps