Working on the future of flocking since 1968

Flocked solutions that drive the industry. Industrial design with purpose.

Global flocked solutions for automotive industry

Specialized in research, development, production and commercialization of flocked solutions.

About TAPLA®

At Tapla®, we have spent over five decades researching, developing and producing technical solutions tailored precisely to each customer’s needs.

We have several flocking lines in constant evolution, large production capacity and a constant R&D effort to meet market needs.

We combine experience, innovation and engineering with purpose and proximity to drive a more sustainable, efficient and human future in the flocking industry.

What do we do?

We have our own laboratory for the research and development of new flocked solutions that meet the highest technical and environmental standards, especially in demanding sectors such as automotive.

We perform rigorous tests based on the strictest industry standards to ensure a product with reliable, long‑lasting performance.

We also provide tailored technical assistance at every stage of the process, from design to implementation, ensuring each solution works where it really matters: on your production line.

PRODUCTS

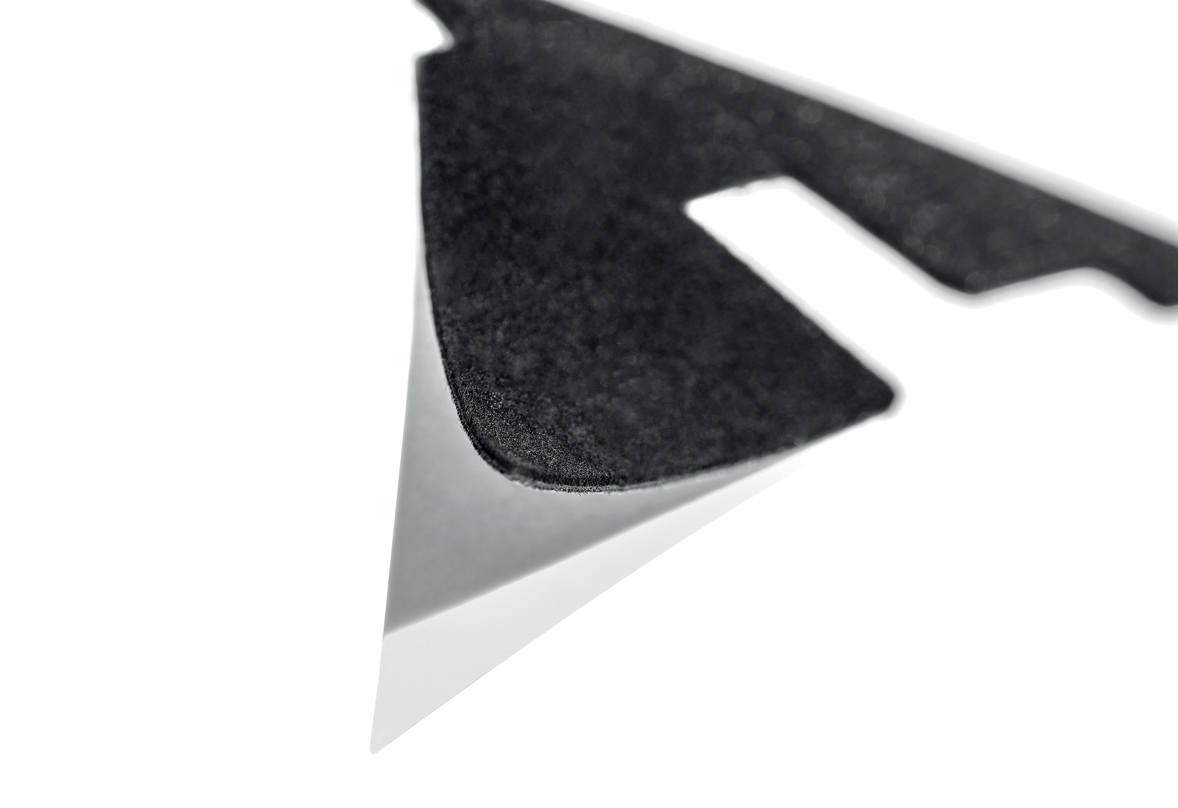

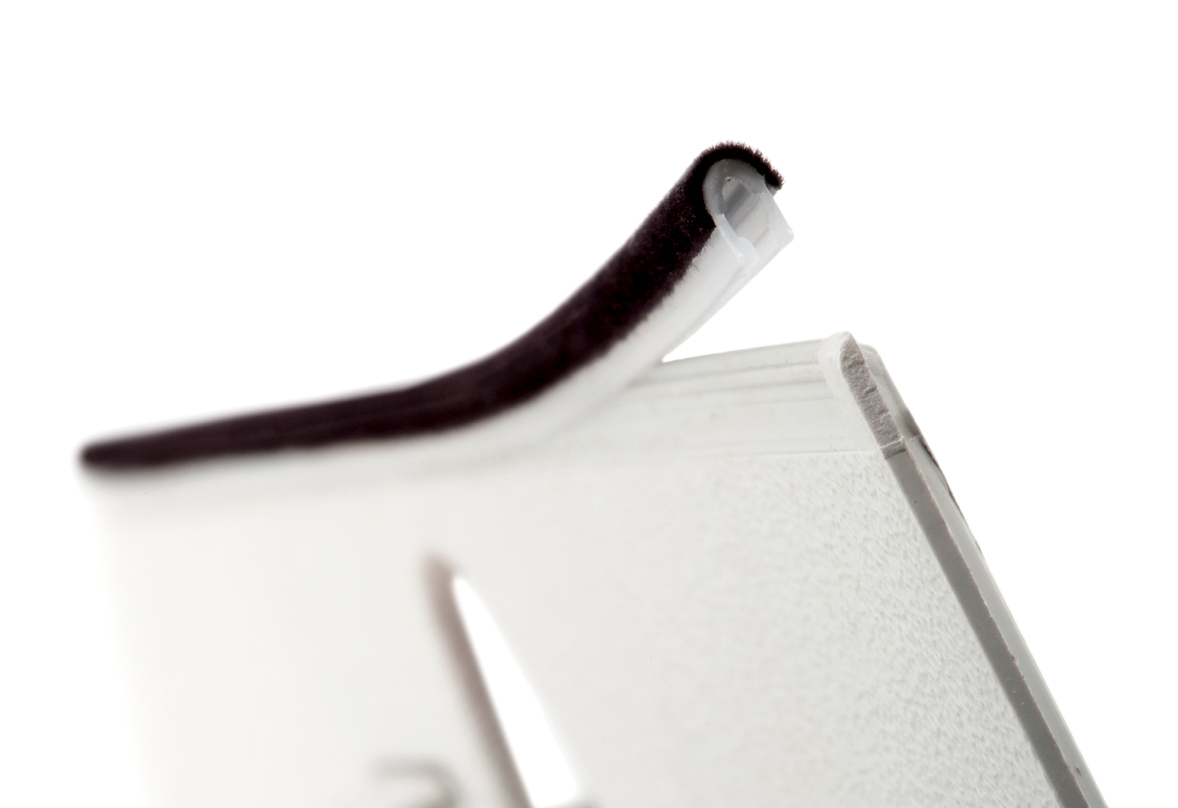

Flocked products for automotive industry

INNOVATION

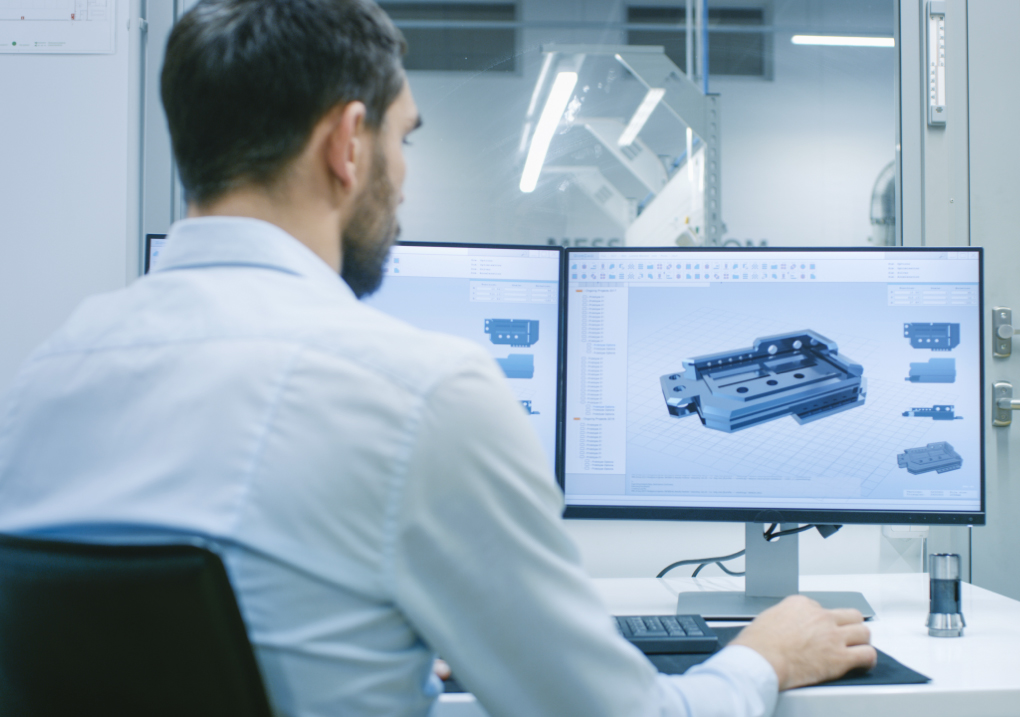

R&D Department

At Tapla®, we understand innovation as a key tool for anticipating our customers' future needs in a constantly evolving market. Our R&D department works with a clear vision: to transform technical needs into concrete, functional, and sustainable solutions. We are committed to the ongoing development of materials, technologies, and processes that enable our customers to differentiate themselves, comply with regulations, and meet industry demands, always with a firm commitment to quality, excellence, and respect for the environment.

Custom developments

We design customized technical solutions that respond to the unique challenges and needs of each context. From the formulation of water-based adhesives to tailored flocking, we adapt technical specifications and compatibilities to ensure functionality, quality and regulatory compliance. Our expertise in materials allows us to offer reliable solutions tailored to demanding environments and providing high added value for our customers.

Constantly evolving technology

At Tapla®, we innovate not only in products but also in processes. We use custom-developed technologies in flocking, cutting, coating application and tooling design. This internal capability allows us to adapt to each project with agility, precision and reliability.

We control every phase of the process to ensure a competitive product with high technical performance that is fully optimized for efficient integration into the production line.

Technical solutions for demanding sectors

We design solutions that are both conceived and manufactured to perform at the highest level and meet the strictest technical and regulatory standards.

Our commitment extends from project feasibility, through design, and implementation, ensuring compatibility and high performance in every application.

SERVICES

Commitment to efficiency and satisfaction in every process

Technical support

Industrias Tapla® has its own technical assistance department to provide support throughout all stages of the project: from its inception (feasibility and design), through to start-up (fine-tuning), and throughout the entire project lifecycle. This includes projects with applications in the extrusion process, as well as any other industrial processes that may require our flocked solutions.

Our assistance ranges from work in our technical office to sending our product application experts to customer facilities for personalized technical assistance. This allows us to collaborate closely with the client throughout all stages of the project, ensuring a clear focus on mutual success.

Taplatape® application

Along with our customers we develop specific application systems for each product, material, and process according to the needs of each project.

We participate in all stages of the flock tape application process, from the design of the necessary tools to its implementation in the plant, ensuring an efficient and optimized process.

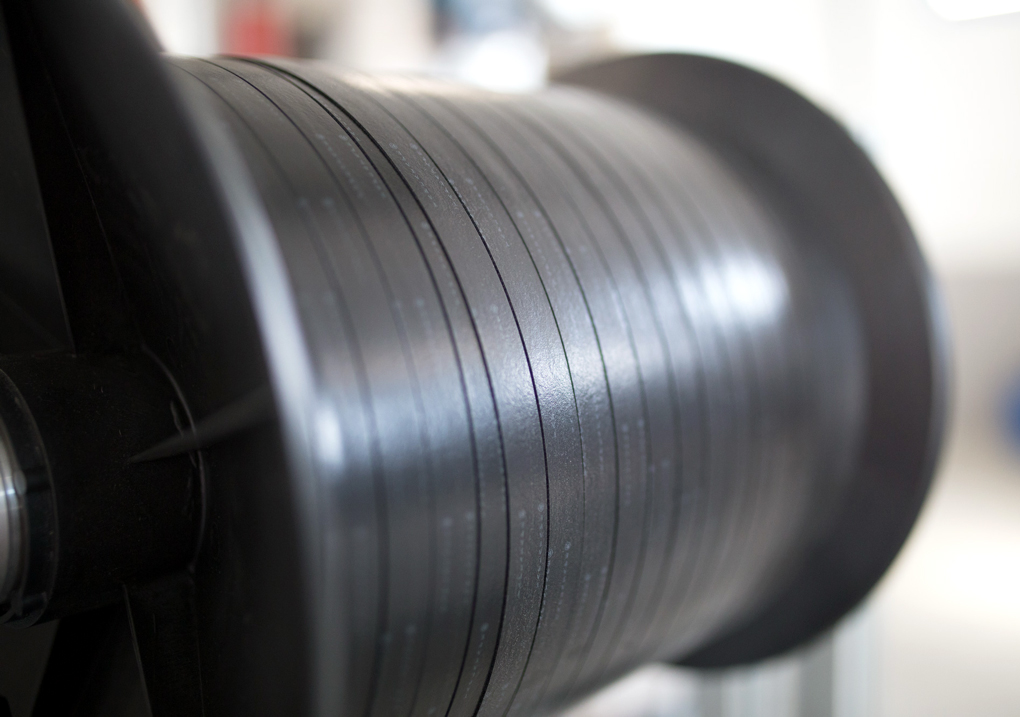

Unwinders

For the effective application of flocked tape, in addition to technical support, applicators, and other parameters, tape unwinding is a process of great importance, as it has a significant impact on the final application result.

As an additional service to our customers, Tapla® offers a simple and competitive solution in tape unwinders to ensure the correct and controlled unwinding of Taplatape®.

Customized Training

We offer a comprehensive, custom training program tailored to the specific technical needs of each client. Our professionals can deliver this training either remotely or directly at the client's facilities, ensuring flexibility, adaptability, and maximum effectiveness.

This ensures that each training program is aligned with the client’s specific technical requirements, providing real and practical value.

Laboratory

We have our own laboratory equipped with the necessary equipment and technology to perform approval and release tests on our products, including aging, tensile, abrasion, and adhesion tests, among others.

We use the most stringent automotive industry regulations and the customers' specific requirements as a benchmark to ensure the reliability of the products we supply.

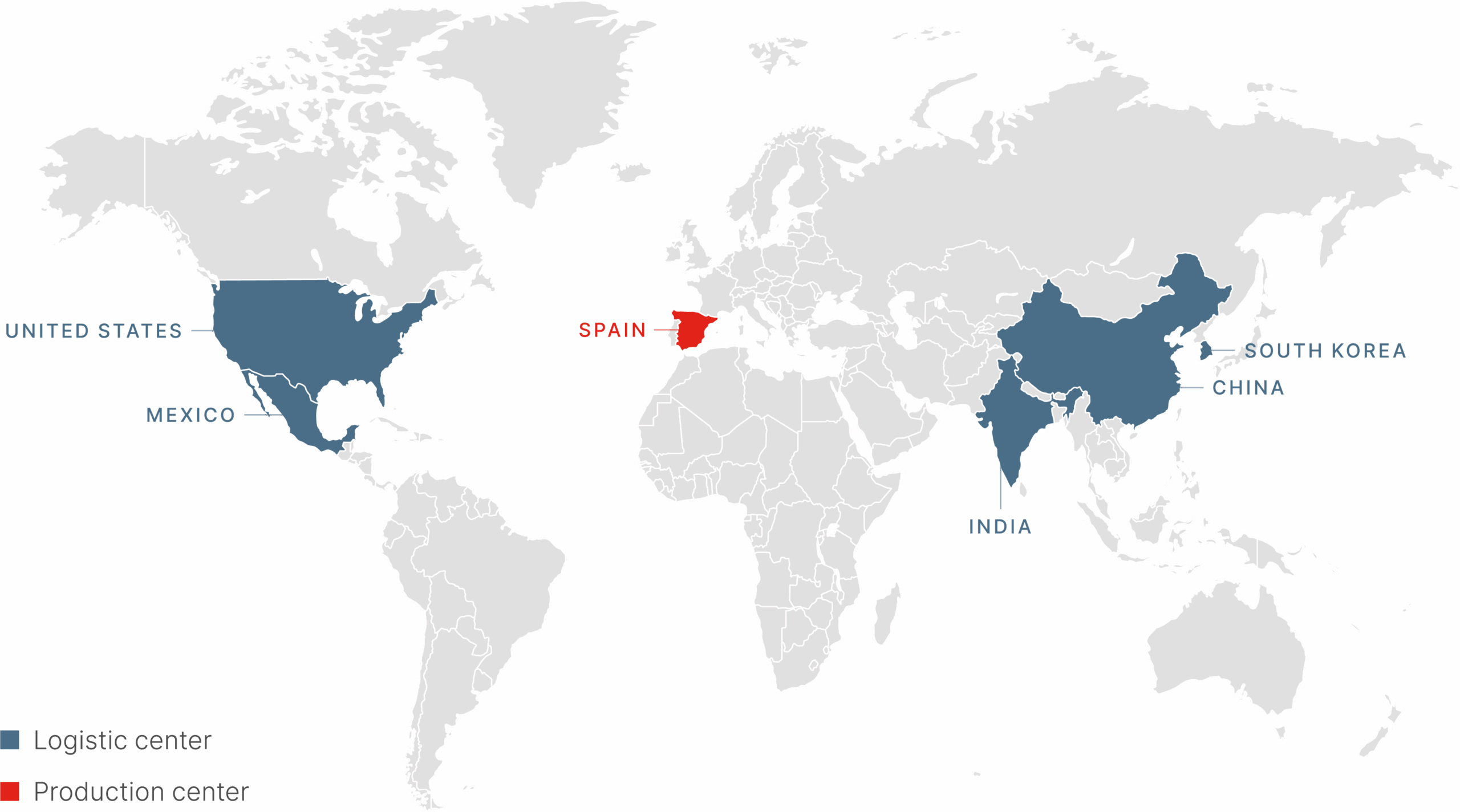

Production and logistics centers

Find our locations around the world.