Taplatape®

The best solution for flocking profiles, reducing complexity and ensuring high performance.

materials

Technical information

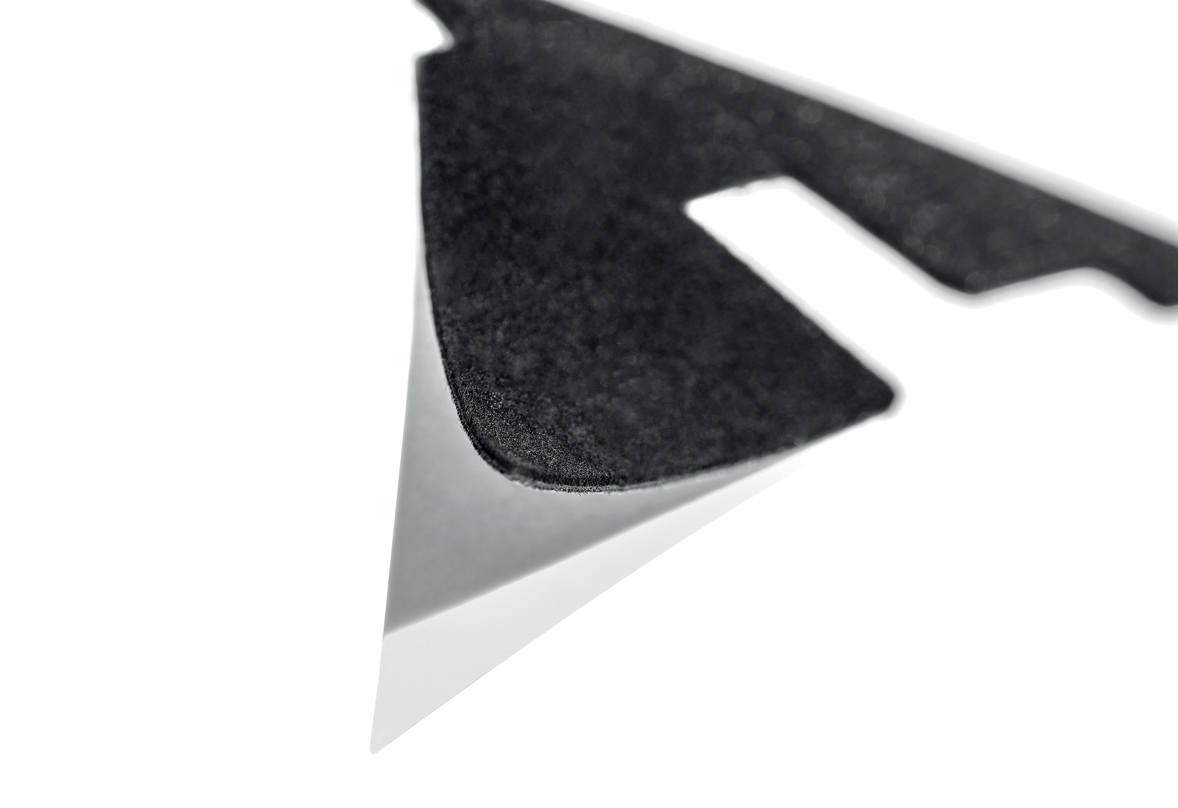

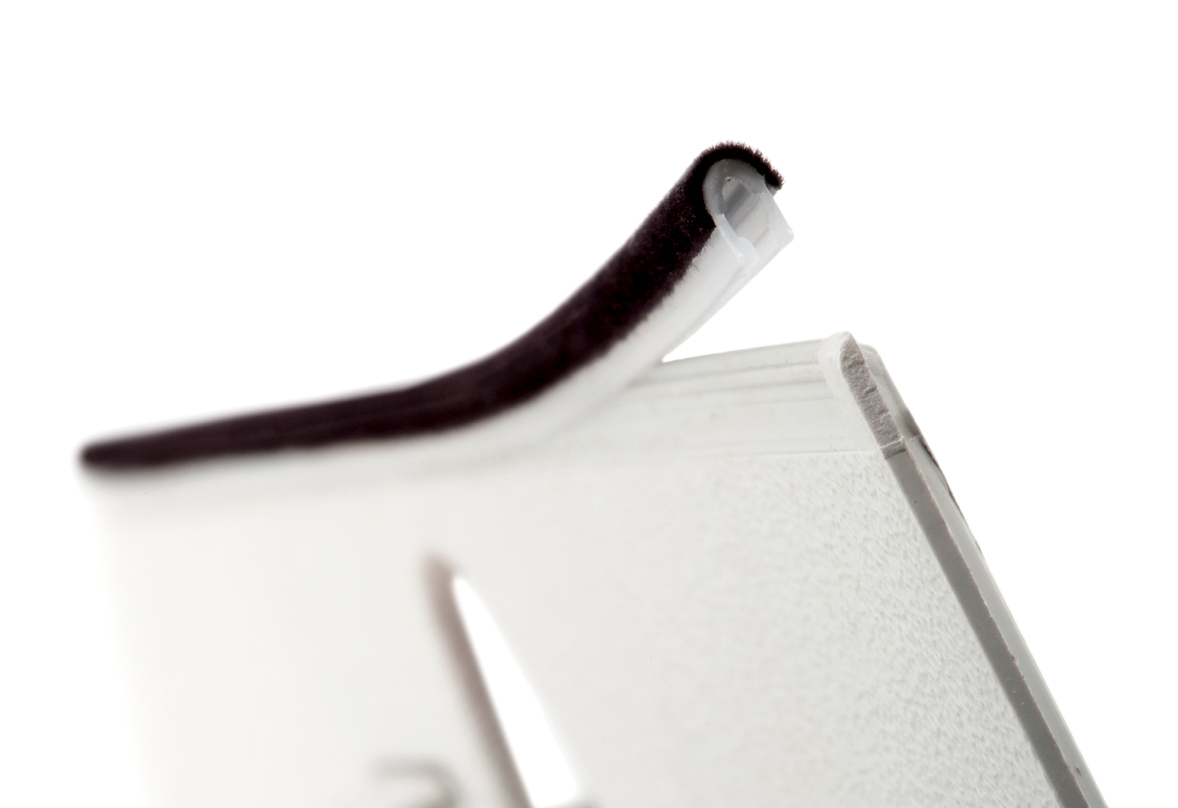

Flocked tape to be applied in extrusion line, ideal for automotive sealing profiles. Designed as a reliable alternative to online flocking: simplifies the process, ensures consistent performance, ensures high fiber density and reduces waste, cost, maintenance and space.

Flock fibers

PES / PA

1,7 / 3,3 Dtex

0,4 - 0,8 mm

Adhesive

Over 30 years of experience in water‑based adhesives.

Support

Compatible with extruded profiles made of TPE, PP, EPDM, PVC and others as required.

Other product options

Color and Coated

Coated

Flocking solutions with various coating options applied to the flocked surface to mitigate the risk of freezing or enhance advanced soundproofing. Thanks to our application technology, a homogeneous and uniform coating application is guaranteed, achieving high performance compared to other methods which directly result in savings for our customers.

Color

Customized flocking solutions tailored to the client's color requirements, designed to achieve an aesthetic finish that meets the highest quality standards.

They are especially suitable for visible areas that require specific development, capable of meeting both functional and visual differentiation expectations.

APPLICATION AND CONSIDERATIONS

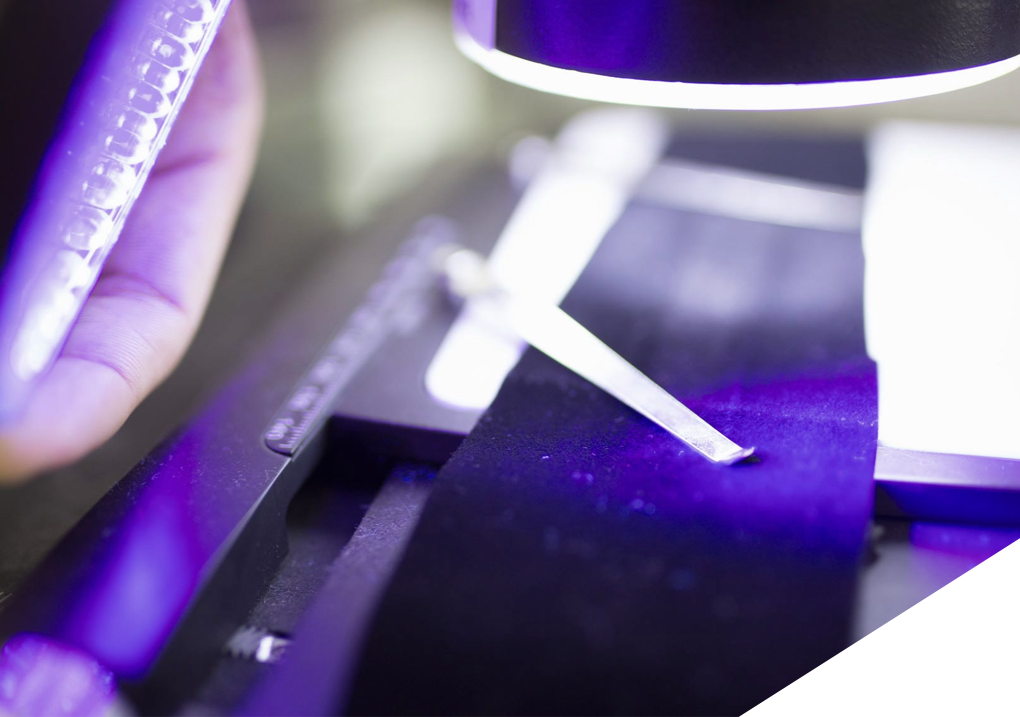

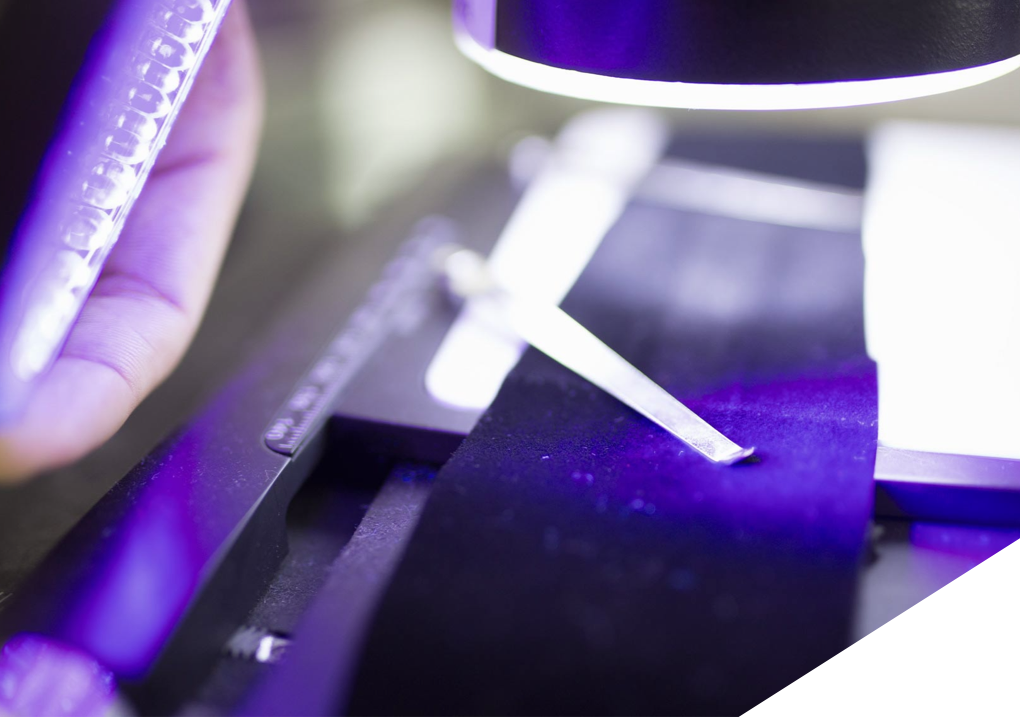

Taplatape® Application

How is it applied?

Taplatape® is physically bonded to the profile using temperature, pressure, and proper guidance during the extrusion process.

This eliminates the need for solvent-based adhesives in the application process and provides greater flexibility for application and adaptation to changes.

It can be applied to thermoplastic or rubber materials, among others, meeting the highest industry requirements.

Considerations for the application of Taplatape®:

- Tape applicator for proper guidance.

- Unwinder for flocked tape spools.

OPTIONS

Application of flocked tape

Inner waist belt

Outer waist belt

Glass Run Chanel

Door seal

BENEFITS

Unique advantages of using Taplatape®

Tape application without line speed limitations

Risks reduction in the flocking process

Flocking space reduction

Manteniance costs reduction

Cleaning costs reduction

High adaptability to changes in specifications and requirements

Waste reduction caused by flocking process

Higher fiber density and greater abrasion resistance

Possibility of incorporating coated flocking without additional steps